The history of the racing engine—and perhaps to a lesser extent the road going engine as well—has been driven by advancements in induction and valve train technology.

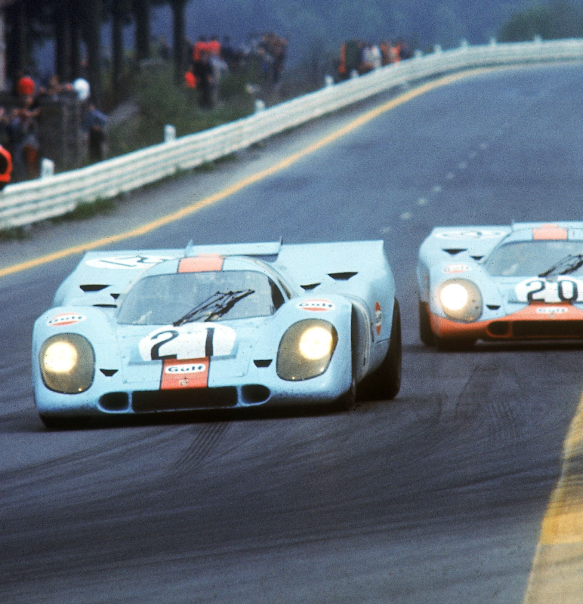

Photo: Dan R Boyd

Once the 4-stroke Otto cycle form of internal combustion engine became the standard, some of the greatest leaps in performance and efficiency came through improvements in the engines ability to “breathe.” Today, despite claims of the internal combustion engine’s imminent demise, a new technological development is poised to revolutionize and improve the gas-burning engine—EAV, or Electronically Activated Valves.

Looking back at the influence of valve train development on racing history, one of the most significant advancements was made in 1912, by Peugeot. As I recounted in this space, last January [Respect for the Charlatans], in 1912 Peugeot made a major commitment to Grand Prix racing and did so by developing a very different type of racing engine, that instead of relying on massive displacement, focused on smaller, higher revving cylinders with better volumetric efficiency. This relatively diminutive 7.6-liter engine (compared to its 14-20-liter rivals!), featured a new double overhead camshaft arrangement that activated not two, but four valves per cylinder. Sound familiar? It should, as that became the archetype for nearly every racing engine that has followed since.

Once racing engines started spinning much faster, a new engineering challenge reared its ugly head, valve float. With conventional poppet valves being closed by spring activation, as engine speeds increased, if the springs weren’t strong enough, they couldn’t keep the valve in contact with the controlling camshaft, resulting in the valve essentially “floating” in air and not closing in time. Since the early metallurgy could only make reliable springs of a certain strength, other technological solutions were sought. One of these was the development of desmodromic valve actuation.

In a desmodromic valve set up, the face of one cam lobe pushes the valve open, while another physically pushes it closed. Developed by Gustav Mees as early as 1896, a version of it was briefly used by Delage in 1914, but this novel form of valve actuation didn’t really see practical racing application until Mercedes-Benz utilized it in the mid-1950s on the W196 Grand Prix and 300 SLR racecars. Later used by the short-lived Scarab Grand Prix effort and by OSCA in their 2-liter, 4-cylinder sports car, the technology was mostly sidelined in automobile racing by advancements in spring technology and the desmodromic’s complexity and sliding friction drawbacks, though it has lived on in motorcycle racing, most notably by Ducatti.

It wouldn’t be until the 1980s when another major change in valve train technology would appear. During this period Renault, began experimenting with replacing conventional coil valve springs, with compressed gas. By using a sealed chamber of compressed gas to close the valve, Renault found that they could eliminate both valve float and spring harmonics, which both severely limited the maximum rpm a racing engine could attain. By 1989, this system was sophisticated enough that a Renault V-10 engine could reach a redline of over 14,300 rpm! Since then, pneumatic valve springs have been a standard for Formula One racing engines…but that may soon change.

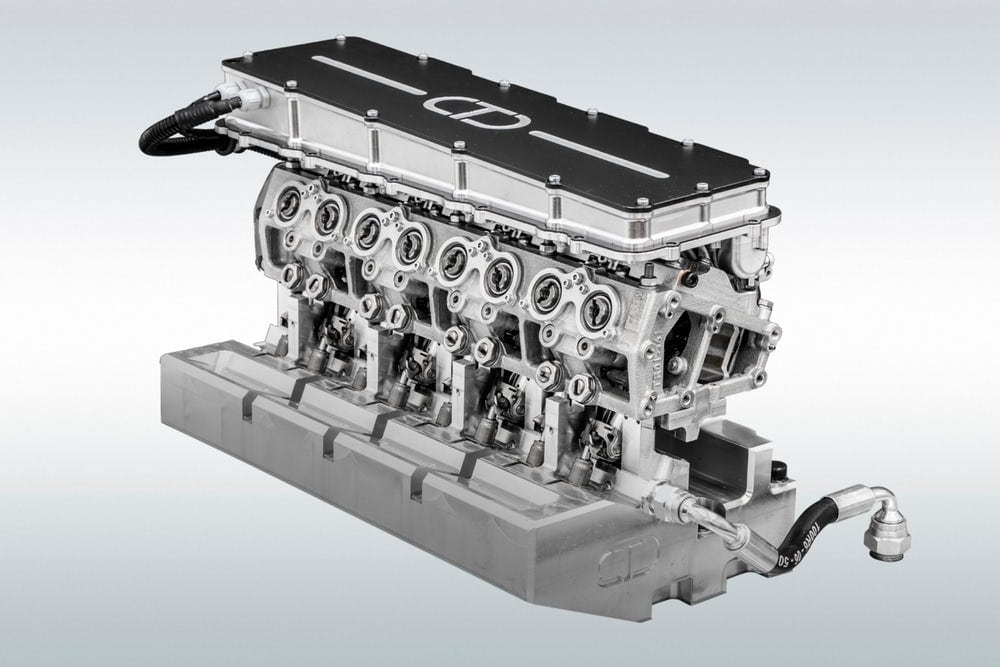

For several years, it has been known that a variety of manufacturers, including Renault, have been experimenting with EAV, or electrically activated valves. In some ways, this could be viewed as an extreme extension of desmodromic activation, in that, instead of relying on a crankshaft driven cam to control valve opening and closing, now each valve has its own electrically driven actuator to open and close any given valve. While this type of advanced system has been experimented with by various manufacturers, a British company named Camcon Automotive has now debuted a completely digital valve system, that could very well usher in a new era in internal combustion engines.

Camcon’s new system, which has been developed in conjunction with Jaguar Land Rover, utilizes an individual cam-type lobe, directly driven by a computer-driven electric motor to control when the valve is opened, how far it is opened and when it is closed. By uncoupling this process from a direct-driven camshaft, theirs is much less internal friction and not only do the valves now have infinite timing variability, but now even the fundamental nature of the combustion cycle itself can be manipulated, in real time. According to Camcon COO Mark Gostick, “What you can do – in principle at least, we haven’t demonstrated it yet – is you can turn the vehicle, for short periods of time, from four-stroke operation into two-stroke operation. That essentially doubles the power output. It gives you, when you need it, a burst of power. In principle, you can do it, for a short time period that’s limited by heat and lubrication factors.

“Two-stroke is one of those things that kind of is, was and always has been the future of internal combustion engines. There’s renewed interest in two-strokes for a number of applications and we might be able to do something interesting there, just for very short periods, so you can get over this problem with small engines in big cars.” Gostick goes on to explain that Camcon’s new IVA, or Intelligent Valve Actuation, can also improve on cylinder deactivation as well, “So if you’re on the motorway and you’re cruising along, you can put it in 12-stroke mode, meaning that every cylinder only fires every third stroke. But it does it over the whole engine, like a roaming cylinder deactivation if you like. A lot of cylinder deactivation just knocks off one or two cylinders, and because it’s mechanical, it always knocks the same ones off, and when you re-engage them, you get hydrocarbon spikes because there’s engine oil building up in the cylinders while they’re not firing. If you do 12-stroking, you keep all the cylinders warm and you stop this build-up of lubricant, so you get the benefit without the penalty when you re-engage four stroke again.”

While Camcon’s new system is predominantly targeted for improving the efficiency of passenger cars—where it is believed it will reduce an engine’s CO2 output by as much as 20%—utilizing this type of a system in racing applications opens up the possibility of another quantum leap in engine performance, similar to that seen with the Peugeot in 1912. At the very least, can you imagine the engine shriek, when a Formula One driver pushes the “pass” button on his or her 15,000 rpm race engine and it briefly doubles down as a two-stroke?!

So will electronically activated valves revolutionize racing? Quite possibly. So if you have any old camshafts in your garage, you might want to hold on to them—I think they are on the verge of becoming collector’s items!