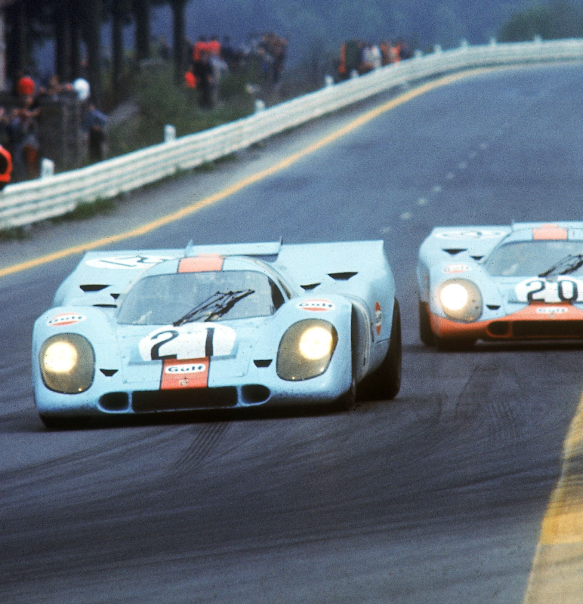

If there’s one thing that sets a vintage racing car apart from a modern one, it’s the use of aluminum. The material had its own aura. Everyone knew the fastest XK-120s, the lightest Austin-Healeys and the quickest of the Ferraris, SL’s, Astons and Masers were distinguished by their lightweight skins formed from sheets of aluminum that had been pressed, rolled, formed or otherwise violently pounded into submission by gifted craftsmen around the world.

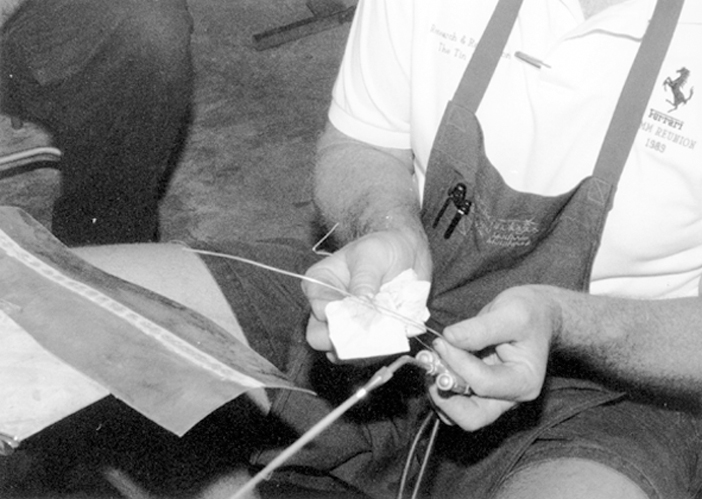

Aluminum had a number of things going for it besides being lightweight. It wasn’t particularly expensive and, in the right alloys, was relatively easy to form. On the downside, it hardens as it is worked and can get brittle. Many early aluminum bodies were attached to a steel framework with steel rivets, resulting in extensive corrosion problems down the road. Damaged areas were frequently patched with a dollop of Bondo rather than a time-consuming reshaping. By the time vintage racing came into being, most of the aluminum bodies from the 1950s were in need of some corrective surgery. However, there were only a few bodymen around the country that were familiar with the idiosyncrasies of working with aluminum, and those that could master the art became much in demand. One of the best of these craftsmen is Kent White, a.k.a. “The Tinman”.

Become a Member & Get Ad-Free Access To This Article (& About 6,000+ More)

Access to the full article is limited to paid subscribers only. Our membership removes most ads, lets you enjoy unlimited access to all our premium content, and offers you awesome discounts on partner products. Enjoy our premium content.

Become a member today!

Already a Member?